Overview of SAP MM Module

What is SAP

SAP is a Enterprise resource planning (ERP) software owned by SAP Germany.

SAP stands for systems Applications and Products in data processing

SAP has various modules like MM, SD, FI, HR, PM, PS, PP, QM which are linked to each other

SAP is a Enterprise resource planning (ERP) software owned by SAP Germany.

SAP stands for systems Applications and Products in data processing

SAP has various modules like MM, SD, FI, HR, PM, PS, PP, QM which are linked to each other

Overview of SAP MM Module

• Processes in Procurement

• Inventory management and physical

inventory

• Pricing in Purchasing

• Invoice verification

Topic 1: Processes in Procurement

• Basics of Procurement

• Master data

• Procurement of Stock Material

• Procurement of Consumable

material

• Procurement of External services

• Contracts and Scheduling

agreements

• Document Release procedure

Topic 2: Inventory management and

Physical inventory

• Goods receipt

• Stock transfers and Transfer

postings

• Reservations

• Goods issues

• Special stocks as below two types

Sub

contracting

Vendor Consignment

• Material valuation and split

valuation

• Physical inventory and cycle

counting

• Movement types

Topic 3: Pricing in Purchasing

• Conditions in purchasing

Access sequence, condition types and

Pricing schema (pricing procedure)

• Price determination

How is price determined in PO

• Customizing pricing

Create condition tables, access

sequence, condition types and pricing procedure

Topic 4: Invoice verification

• Basics of invoice verification

• Taxes cash discounts and foreign

currency

• Variances and invoice blocking

• Invoices for POs with Account

assignment

• Delivery costs

• Invoices without reference to POs

• Credit memos

• Invoice parking

• Automatic settlements

Basics of

Procurement

In Basics

of Procurement we will study about below sub topics

• Organizational Structure

• Types of Purchasing organization

• Procurement cycle – Creation of

purchase order to invoice verification

Organizational Structure in SAP

MM

Organizational Structure in SAP

MM

• Client is the organizational unit

within the R/3 system with its own data, master records and set of tables. In

business perspective client forms a corporate group.

• Company Code is the central organizational

unit of financial accounting. A company has its own balance sheet.

• Plant is a organizational unit where

production, procurement, plant maintenance and material planning is carried

out.

• Storage location is a organizational unit within a plant that

allows differentiation of stocks.

• Purchasing organization and

Purchasing group

A

purchasing organization negotiates conditions of purchase with vendors for one

or more plants.

A purchasing group is a buyer or a

group of Buyers responsible for certain purchasing activities.

Types of Purchasing Organizations

• Plant specific purchase

organization

Here the purchasing organization

is responsible for procuring materials for one plant only.

• Cross plant purchasing

organization

A

cross plant purchasing organization is set up for each company code. This

purchasing organization procures materials for all plants assigned to the

company code.

• Cross company code purchasing

organization

In

a cross company code purchasing organization, we cannot assign a company code

to purchasing organization in customizing.

In

this case when we create a PO the systems asks to enter the company code for

which we have to procure materials.

Plant

specific purchasing organization

In plant-specific procurement, a purchasing organization is responsible for procuring materials for one plant only.

In plant-specific procurement, a purchasing organization is responsible for procuring materials for one plant only.

Cross

plant purchasing organization

A cross plant purchasing organization is set up for each company code. This purchasing organization procures materials for all plants assigned to the company code.

A cross plant purchasing organization is set up for each company code. This purchasing organization procures materials for all plants assigned to the company code.

Cross

company code purchasing organization

In a cross company code purchasing organization, we cannot assign a company code to purchasing organization in customizing.

In this case when we create a PO the systems asks to enter the company code for which we have to procure materials.

In a cross company code purchasing organization, we cannot assign a company code to purchasing organization in customizing.

In this case when we create a PO the systems asks to enter the company code for which we have to procure materials.

Procurement

cycle

Procurement cycle consists of below steps

Procurement cycle consists of below steps

• Determination of requirements: The user department creates a PR

for a material and passes it to purchasing department. If we have set up a MRP

procedure for a material in the material master the R/3 system automatically

generates a PR.

• Determination of source of

supply: The buyer determines the sources

of supply. If there is a vendor for the material then a PO is raised by Buyer.

If there is no source the buyer raises request for quotation (RFQ) and sends to

possible sources.

• Vendor selection:

The system

compares the prices of various quotations and automatically sends rejection

letters (to high price quotations) and selects the vendor with least price.

• Purchase order processing: When we are entering PO’s the

system provides data like

material PO text price etc. PO is created and sent to vendor.

• Purchase order monitoring:

The buyer

monitors the status of PO at any time and checks if goods or invoice has been

received for the PO item/items. If goods are not received system sends reminder

letters automatically.

• Goods Receipt:

When the goods

are received in stores the system compares the goods receipt qty with PO qty

and posts GR.

• Invoice verification:

After goods

receipt is done the vendor invoices are checked for accuracy of prices and

other contents and invoice is posted.

• Payment processing:

Financial

accounting deals with payments. Payment is done to vendor by Finance

department.

Purchase

Requisition

• PR’s are created manually by user

or automatically by system by MRP procedure.

• When PR is created for materials

with material master record the system captures the data from material master

record into the PR. The purchasing dept. converts the PR into RFQ, PO or

outline agreement.

RFQ/Quotation

• The buyer can enter RFQ manually

or automatically. The RFQ is

sent to suitable vendors whose

address is taken from vendor master records.

• The vendors will send their

quotations or rejection letters. The buyer enters the conditions, price &

delivery dates of quotations in the system.

• The system compares the

quotations and finds the most favorable vendor.

Purchase

order

• A PO is a request to a vendor to

supply certain goods or services under stated conditions.

• A PO can be created without

reference, w.r.t a PR, RFQ or another PO.

• When we enter PO data the system

suggests ordering address, terms of payment and incoterms from vendor master

record, material text from material master record and price from purchasing

information records. The PO is sent to vendor

Goods

receipt

• The goods receiving dept. will

check the quantity & quality of item received w.r.t PO. When we post goods receipt the system creates

a material document (GRS).

• The system also creates one

accounting document which records the

effect of goods movement on value of stock.

• The PO history is automatically

updated in the system.

Invoice

processing

• When we enter a invoice w.r.t a

PO the system suggests data from PO and goods receipt for PO. (For data like

vendor material, qty, terms of payment etc).

• If there are discrepancies

between PO, goods receipt and invoice the system blocks the invoice for

payment.

• If the invoice is O.K. the system

posts the invoice and financial accounting dept makes payment to vendor.

Exercise

- Create a Purchase order, Post Goods receipt and Post Invoice

Create

Purchase order ME21N

Change

Purchase order ME22N

Display

Purchase order ME23N

Vendor –

245

Purchasing

org – 1111

Purchasing

group – 001

Company

code – 1111

Material

– 3424

Qty – 10

Price –

11

Delivery

date - Today

Plant –

1111

Storage

loc – 1111

Tax code

GX

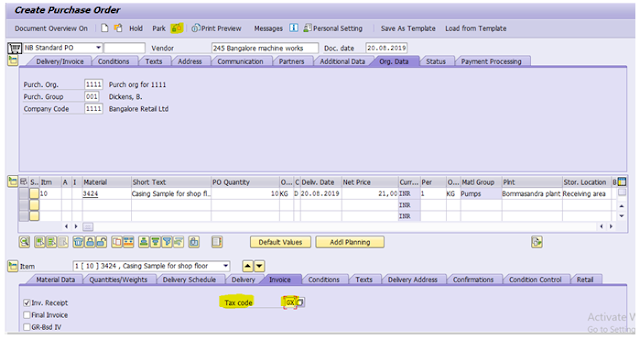

ME21N

Input

the data as shown highlighted in yellow

Press

Enter

In the

invoice tab page input Tax code GX

Click

Check button

We get

message “No messages issued during check”

Click

Save

Exercise: Post Goods Receipt for

Purchase order

Transaction

code – MIGO

PO

number – previously created PO

Plant –

1111, movement type – 101

Date –

Today, Delivery Note – REF-1555

Qty

received – 10 Pc

Check

Item OK

Click

Check and Post

Note

down the material document number created

Go to ME23N

PO display and in PO history tab page we can see the material document number

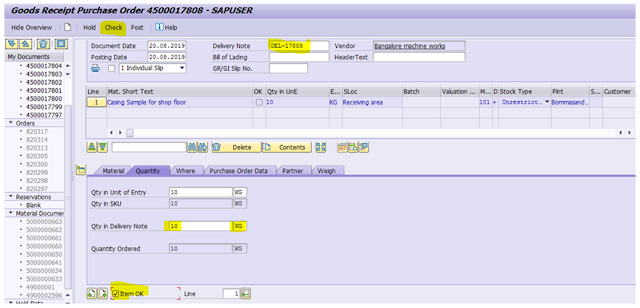

MIGO

Select Goods Receipt and Purchase order

Input the previously created PO 4500017808, Plant 1111, GR

Goods Receipt 101 movement type

Input Delivery # DEL-17808

Qty in Delivery Note 10 KG

Check Item OK

Click Check button at top

We get message Document is OK

Click Post button at top

Material Document number – 5000000670

Display the material document in PO history

ME23N

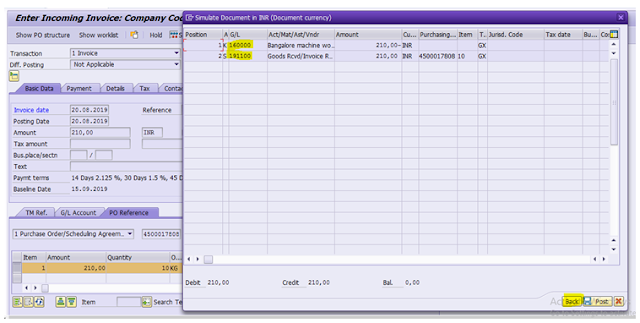

Exercise: Post Invoice for the Purchase order

MIRO

Select Invoice

I put Invoice date – Today

Rreference – Our PO number

In PO Reference tab page select Purchase order/Scheduling

Agreement

Input PO # 4500017808

Also select Goods/service items + planned delivery costs

Enter

In next screen above we will see Balance as 210 Rs which is

equal to PO amount 210 Rs

Input this in Invoice Amount field in Basic Data tab

Enter

The Balance field becomes green which means the invoice

amount is correct

Click Simulate button at top

A new pop up window will open and we can see the G/L Accounts

to which the amount is posted

Click Back

Save

Invoive no 5105609252 created

Display Invoice in PO history

ME23N

In Purchase Order History tab in Item details, we can see the

Invoice document number

No comments:

Post a Comment